OUR PRODUCTS

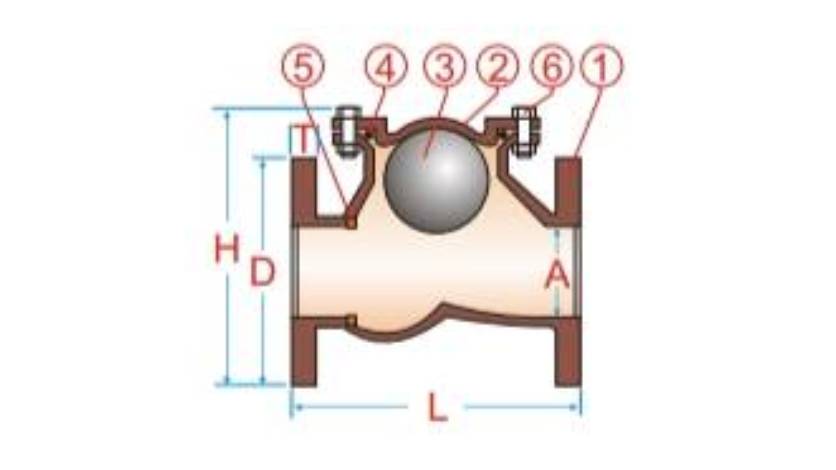

Ball Check Valve Flanged

OMI Ball Check valve is a product designed and manufactured by our R&D Team. These are originally ball-type non-return valves and are much more efficient than the flap-type valves.

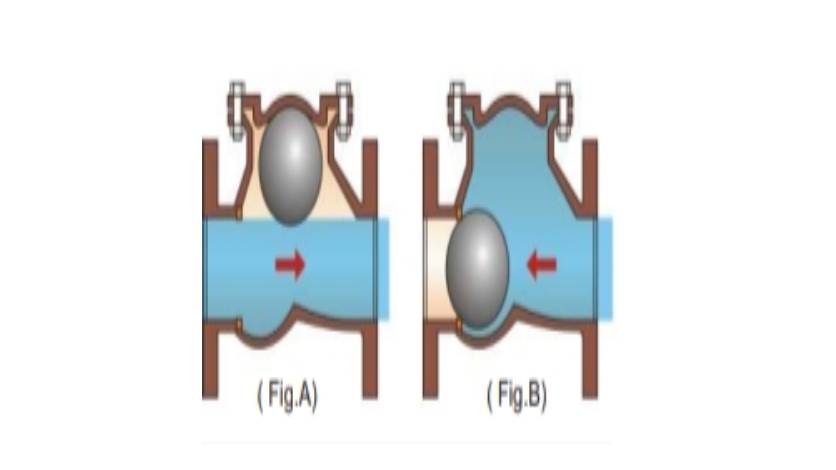

A very simple and robust design with no mechanism involved. The heart of the ball valve is a rubber-coated ball. The mechanism of the hinge pin disc used in conventional check valves is eliminated and a rubber-coated ball to arrest flow media in return condition.

As the pump starts, the ball moves out totally from the flow path when the pumping is on giving a full bore maximum flow/discharge with minimum head loss. As the pump stops, the ball rolls back and seats perfectly in the rounded valve seat ensuring a complete leak-proof sealing.

| Nominal Bore Size | 1.25”, 1.5”,2”,2.5”,3”&4”. |

| Body Test Pressure | 0.5 MPa |

| Seal Test Pressure | 0.02 MPa |

| Liquid | Clear Cold Water |

Applications

| Material of Construction of Valve | |

| Part Name | Material |

| Body | Cast Iron |

| Ball | Nitrile Reinforced |

| Paint | Anti Rust Black Paint |

| Sealing Ring | Nitrile up to 80 mm / L T Bronze for 100 mm |

| Fasteners | Carbon Steel |